VIRTUAL MONITORING - PREVENTIVE MAINTENANCE

CAPT, TEINCO and SCHNEIDER join forces to offer the food industry the possibility of remote maintenance of their production lines.

CONNECT TO YOUR EQUIPMENT ANYWHERE IN THE WORLD

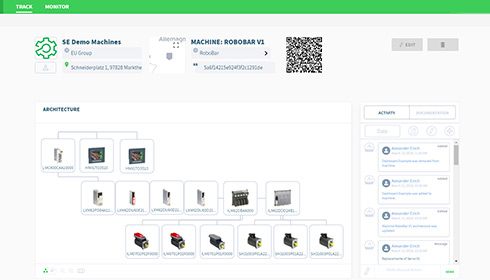

This Tele-maintenance service consists of three parts:

- TRACK: simple location of machines, creation of profiles related to architecture, log book, machine history and documentation.

- MONITOR: Collect and visualise machine operating data.

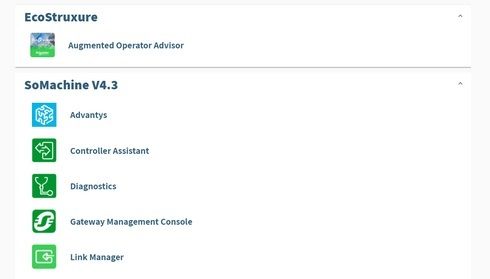

- FIX: control and maintenance tools via the cloud.

What it allows us to do:

- Access all equipment data anytime, anywhere.

- Offer our customers a more efficient and faster service.

- Tele-maintain any machine installed anywhere in the world.

- Read and update program files from the web browser.

- Better preparation of on-site maintenance interventions.

Our Tele-maintenance can be installed in any equipment of the food processing line that has an automaton, industrial pc, etc,. For example, CAPT is already remotely managing autoclaves and cookers.

|

|

|

|

|

|